MIM-Master Neo (Next Generation MIM)

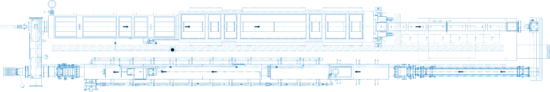

The MIM-Master Neo continuous walking beam sintering furnace and the corresponding operation procedure for the new furnace represent the newest development for continuous furnaces for the production of metal injection molding ferrous and non-ferrous products. The MIM-Master Neo furnaces are the next generation of continuous furnaces for the production of MIM components.

The MIM-Master Neo is built based on our well-established state of the art technology which enables a coupling of continuous residual debinding and sintering processes, the MIM-Master series.

The new design scrupulously combines the low-vibration ultra-smooth charge tray movement on the MIM-Master walking beam with an increased production capacity, which is more than 120% greater than the last generation MIM-Master. Furthermore, this is achieved with a smaller furnace footprint, thereby reducing the gas & energy consumption by about 40% and the investment costs by approx. 35%, relative to the last generation design, taking an example of a MIM-Master 10XL.

Additional advantages of MIM-Master Neo are its availability with the new and improved 3rd generation Continuous Catalytic Debinding unit. A new multi-level integrated temperature control (CQI-9 TUS/SAT compatible) is supplied as a standard. In addition, recent developments such as the two-stage torch ensure that gases that leave the furnace are odorless and environment friendly.

Novel complimentary modules could, moreover, be coupled with the MIM-Master Neo: e.g. the ICS Iso-Cool System. This ensures controlled cooling rates of up to 180 K/min uniformly through all product layers, or the Hydrogen Generator (HG), for H2 generation inside the equipment with no additional tank and H2-piping required from the customer side.

For the production of CIM products our product range now also includes an innovative “Next Generation” continuous debinding and sintering furnace for CIM.