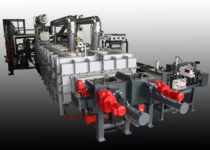

Pusher Type Sintering Furnace PTS

Pusher furnaces – aka skillet furnaces – are represented in many processes. We at CREMER have specialised in processes under inert or reduced atmosphere. Thus, we offer pusher furnace technology for reducing, sintering, carburisation, and calcination.

In this process, the parts lying on charge carriers are pushed through the furnace. Therefore, the overall length is limited. Often, we install a belt in the cooling zone to reduce the force on the charge carriers and to maximise the heated length.

Pusher furnaces equipped with a vacuum lock can be used at process temperatures of up to 2500 °C. These HT-pusher furnaces are equipped with high-temperature resistant electrical graphite heaters and graphite insulation. This allows process temperatures of up to 2500 °C (refer to CARBIDE2500 or refractory metal powders for more information).